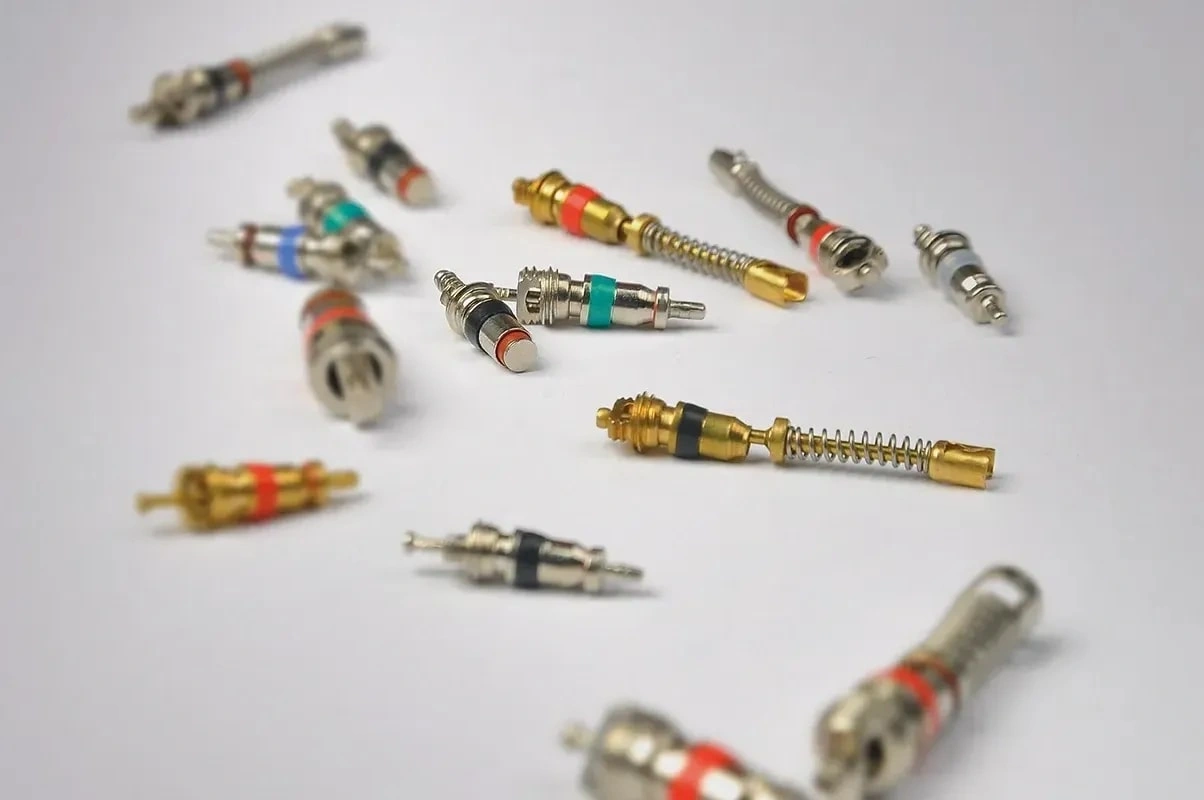

A green valve core refers to a valve core manufactured using low-lead, eco-friendly materials and fully compliant with international environmental standards such as ROHS and REACH.

With the growing awareness of environmental protection and sustainable manufacturing, the valve core industry has also embraced green innovation. Environmental valve cores meet the demand for environmentally friendly products. They reduce environmental impact during production, contain lower levels of heavy metals—especially lead and provide safer and more sustainable solutions for applications that prioritize environmental protection.

As a company committed to sustainable development and environmental responsibility, TONTRON began developing and producing eco-friendly valve cores as early as 2012. Today, we have maintained stable production for over 14 years. All copper components are made from low-lead raw materials, and all eco-friendly materials are processed in separate production lines with strict anti-contamination controls. This mature management process ensures consistent quality and compliance with ROHS, ELV, REACH, POPs, EN71-3, while supplying low-lead valve cores to numerous international customers.

Material Standards:

Eco-friendly materials are defined as materials whose hazardous substance content meets ROHS / REACH standards. For metal components:

· Cadmium (Cd) < 100 ppm

· Lead (Pb) < 1000 ppm (TONTRON uses copper with Pb < 100 ppm)

· Mercury (Hg) < 1000 ppm

· Hexavalent Chromium (Cr6+) < 1000 ppm

For non-metal components:

· For non-metal components:

· Polybrominated biphenyls (PBBs) < 1000 ppm

· Polybrominated diphenyl ethers (PBDEs) < 1000 ppm

· This ensures that TONTRON’s green environmental valve cores are safe, sustainable, and compliant with global environmental standards.